Plen Medical-Crude Oil Centrifuge Machine Center

Your Reliable and one of the best Crude Oil Centrifuge machine manufacturers in China

The crude oil centrifuge is a device that measures the water and sediment content in crude oil.

After measuring the contents, it plays an essential role in ensuring sedimentation through proper division—the centrifugation of crude oil assists in petroleum applications.

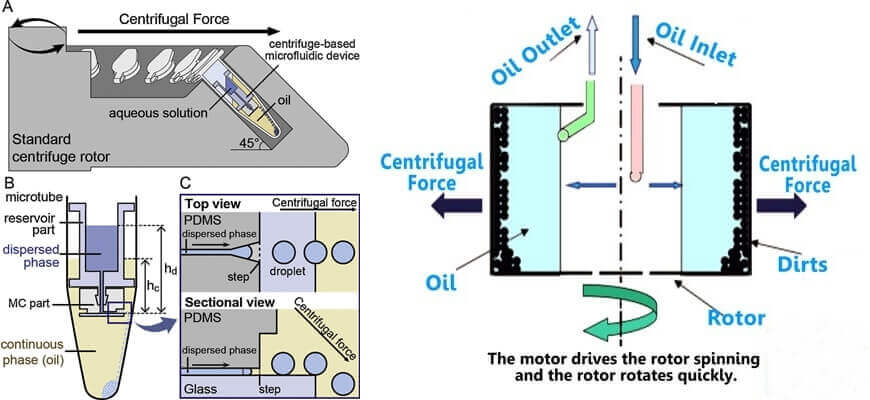

The crude oil centrifugal separators follow the centrifugation process.

With the help of centrifugation force, it helps to separate the different particles within the solution. Hence, crude oil testing equipment separates crude oil and water.

The centrifuge may be used in different industries like ceramics, abrasives, animal feed manufacturing, and more.

However, the crude oil centrifuge is mainly used in the petroleum and oil industry. It helps to clean the petroleum from all the harmful impurities.

Tabletop Heating Crude Oil Centrifuge Machine for sale PM10T

What is the purpose of oil centrifuge?

Petroleum centrifuge is just the opposite, it needs a heating function, and the temperature is controlled between 10-80 degrees.

The rotation speed is about 5,000 rpm, mainly used to separate the water in the oil. It is also called a centrifuge for determining the moisture content of crude oil.

Why is it important not to stop the centrifuge abruptly?

Centrifuge is a high-speed rotating and separating instrument, and its built-in rotor rotates very fast. During use, it is easy to cause damage to the rotor and also hurt itself.

What tube do I use for crude oil centrifuge?

There is one crude oil centrifuge machine regarding to your requirement.

The max capacity of PM10T is 4*100ml,and the max speed is 3500rpm.

Over the years, crude oil centrifuge machine has become extremely popular and common. They are used on a massive scale in the industries.

Whether you need to produce medicines or various lubricating fluids, the crude oil centrifuge can be of great help.

Tabletop Heating Crude Oil Centrifuge Machine for sale PM10T

The oil Centrifuge working principle is quite comprehensive and straightforward.

The Centrifuge has different parts like the inlet, outlet, and separator. Each of these parts has been designed to ensure clean crude oil is obtained in the process.

The separator has a spinning vortex which helps to filter the solid impurities from the oil. The collected solid impurity is further sedimented at the bottom of the division.

The separator usually moves out the high-density liquid with the contaminants.

Hence, when using the oil centrifuge, the oil is collected while water is removed from the system and other contaminants.

The water is removed from the entire machinery through the discharged outlet.

Since the collected oil is still in the machine, one can quickly obtain it from the separator.

The separator has a suction orifice that helps in the removal of toxic elements.

The crude oil centrifuge helps to bring high-quality or impurity-free oil to promote better use across petroleum applications.

The centrifuge machine makes it easier for everyone to see the separation process of sediments and water.

To ensure proper centrifuge method, the crude oil centrifuge will help separate water and sediment in crude oil.

Crude oil contains many impurities and water, which is why many companies often find it tough to get high-quality petroleum.

As per the requirement, the impure crude oil is poured into the machine, which follows a comprehensive sedimentation process.

It filters the liquid and solid sediments. In terms of crude oil, water is heavier than the sediments of oil.

Hence, after the oil is sedimented into the separator box, the high-density liquid water is removed from the system.

After the separation of liquid in the rotary space, it is removed through the tunnel.

The crude oil centrifuge collects the sediment at the bottom of the separator box.

These sediments are easy to collect from the vortex of the separator. The companies can further proceed to collect the segregated deposit from the suction space.

The crude oil centrifuge offers a high force to ensure the proper separation of elements.

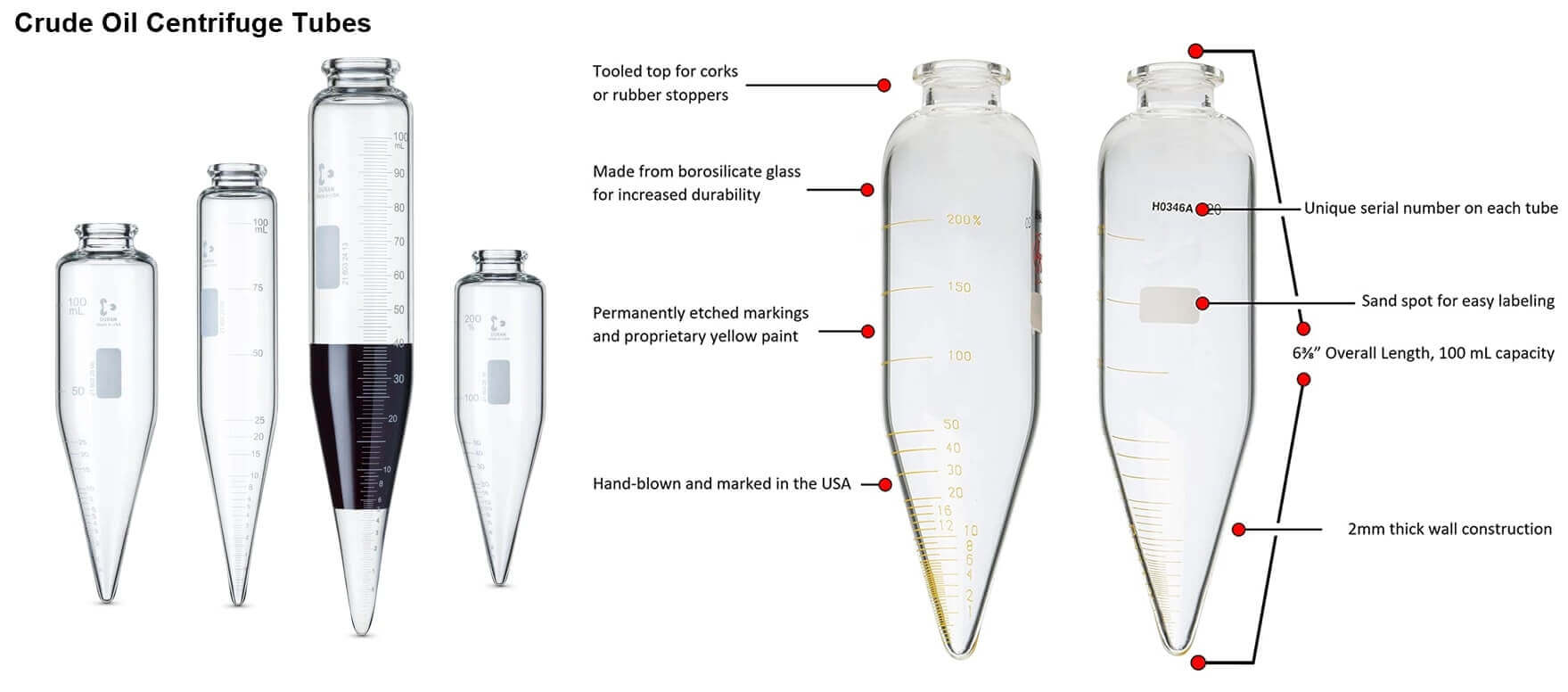

The crude oil centrifuge parts often differ depending on the function. The pump and tubes are the essential parts.

The crude oil centrifuge tubes are found in laboratory tubes.

These machines usually spin faster than normal and play an important role in ensuring the proper separation of sediments and liquid materials.

The crude oil Centrifuge Tubes are usually made of plastic and glass.

These tubes may differ in size depending on the function they need to serve.

These also look similar to the miniature tubes that often have tapered tops.

The standard crude oil Centrifuge tube usually ranges between 0 mL to 50 mL and is in the shape of a four-cone.

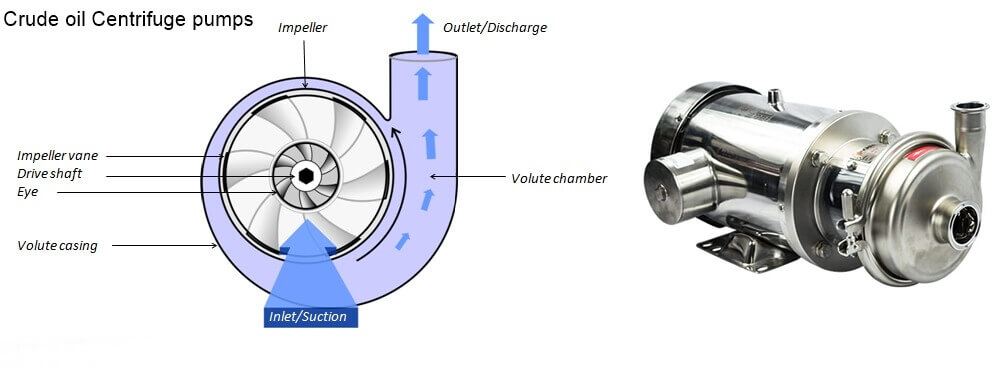

The Centrifuge pumps are extremely beneficial for the oil and gas industry.

The performance of the pimps eventually drops depending on different factors such as high surface roughness and more viscosity.

Moreover, the design of the impellers also has a huge impact on the centrifugal pump performance.

The crude oil centrifugal pump may have one or more impellers that are responsible for fluid rotation.

Furthermore, they are also responsible for putting in the Centrifugal force to remove the liquid from the discharge pump.

The crude oil Centrifuge pumps play an important role in supporting the multiphase pumping application.

Apart from that, these can also be helpful in various activities such as electrical submersible pumps.

The crude oil centrifuge pumps are mighty as they can easily withdraw the low viscosity liquid quickly.

Furthermore, depending on the requirement, these are also responsible for pumping a hundred gallons of liquid.

The Centrifugal pumps can easily manage liquids with low viscosity as they do not have vapors and solids.

These usually operate at high pressure and flow rate to ensure proper refining.

One of the main reasons industries use Centrifugal pumps is that there is no risk for leakage, thereby preventing an accident.

The crude oil Centrifuge pump has a straightforward design. Despite being compact, it is straightforward to use these and are quite compatible too.

Since these are quite durable, it helps to manage the oil drilling procedure too.

However, it is essential to ensure proper crude oil Centrifuge maintenance because they may be prone to damage due to overheating.

The basics of using a crude oil Centrifuge machine is to understand the working principle of the machine.

The sample needs to be poured into the machine for sedimentation and separation.

As per experts’ advice, it is extremely crucial to maintain the speed of the Centrifuge machine.

The standard speed for ensuring proper sedimentation and separation is 7000 rpm.

The crude oil Centrifuge machines follow the process of filtration and oil circulation. It works similarly to dialysis procedures.

The gravitational force generated due to high-speed results in the impurities being thrown out.

Furthermore, it helps to withdraw oil into the machinery while keeping out the impurities and high-density fluid, for example, water.

It follows the proper separation of water and sediment in crude oil by the Centrifuge method.

However, the entire process needs to be carried out in a controlled environment.

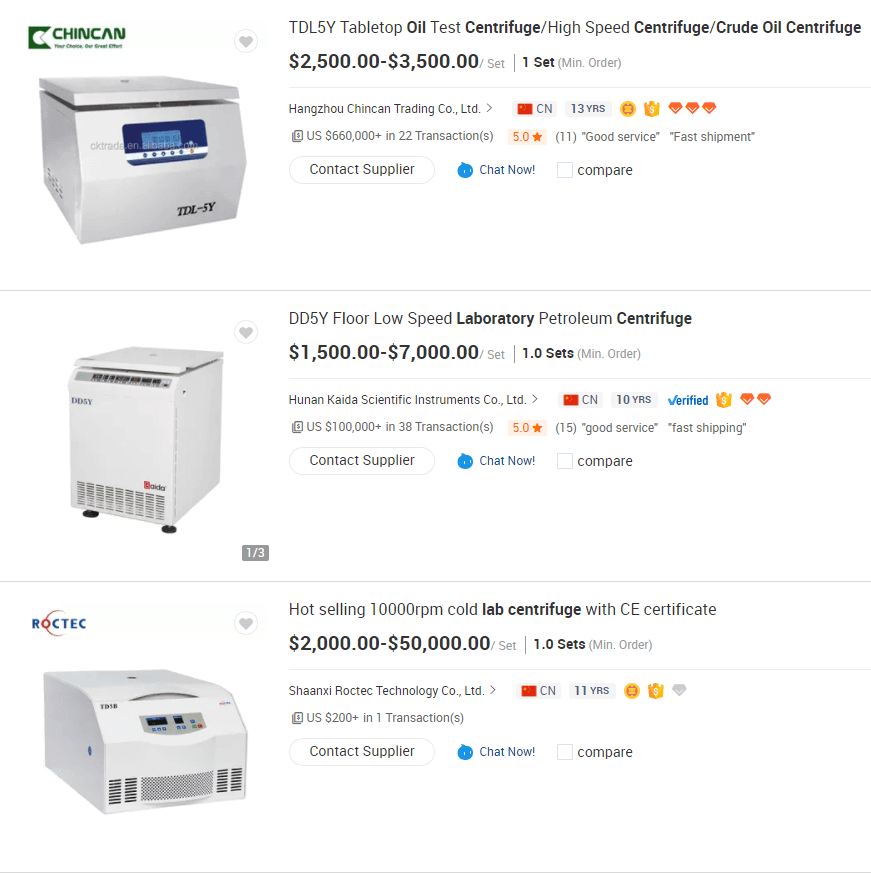

The crude oil Centrifuge price significantly varies depending on the source you’re purchasing the machine from.

Several online sources will promise to give you the best machine at the most affordable rates.

However, it is advisable not to fall into the trap of affordable rates.

If you need a crude oil centrifuge for sale, you need to do proper research.

Moreover, it is best to choose an updated one. The updated models of crude oil Centrifuge are all certified.

Many centrifuge manufacturers also provide you the option of customization.

Before choosing a crude oil centrifuge, it is necessary to measure the speed and compatibility.

The stronger material you choose, the higher the durability will be. Therefore, it is best to choose a carbon steel Centrifuge.

Crude oil Centrifuge maintenance is essential. Since these machines have to deal with crude oil and separate the water and sediment, it eventually becomes prone to impurities.

Crude oil contains several impurities that can bring down the lifespan of a machine.

Hence, all the machine ends need to be cleaned from time to time to avoid the accumulation of any unwanted liquid.

A lube oil can be extremely beneficial for crude oil Centrifuge maintenance.

This is mostly because it will help maintain the machine’s smoothness and promise better performance and durability.

If the crude oil Centrifuge breaks down, the first thing to check is the warranty period.

If it is still under warranty period, the specific company will be responsible for repair.

Crude oil Centrifuges are extremely durable and long-lasting.

However, regular maintenance will help to avoid the risk of repair. Cleaning and repairing the Centrifuge will help to maintain speed and efficiency.

Furthermore, it will also help to ensure proper distribution of speed.

Moreover, if it is being cleaned or repaired through an oil cleaner, it is necessary to maintain the speed.

The level control base should be flexible enough to accept installation and mounting.

Crude oil Centrifuge is expensive but efficient. This is one of the best choices to make for the proper separation of the elements.

Hence, a Centrifuge can help to obtain pure petroleum in a short time.